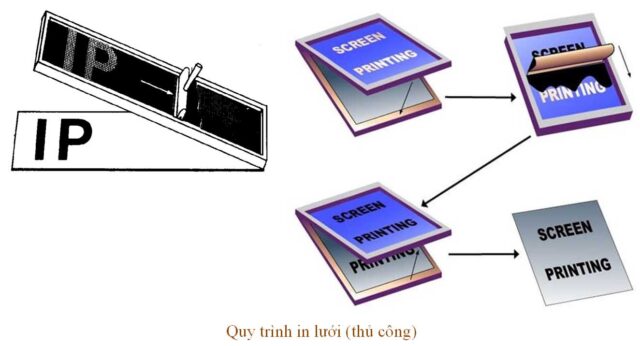

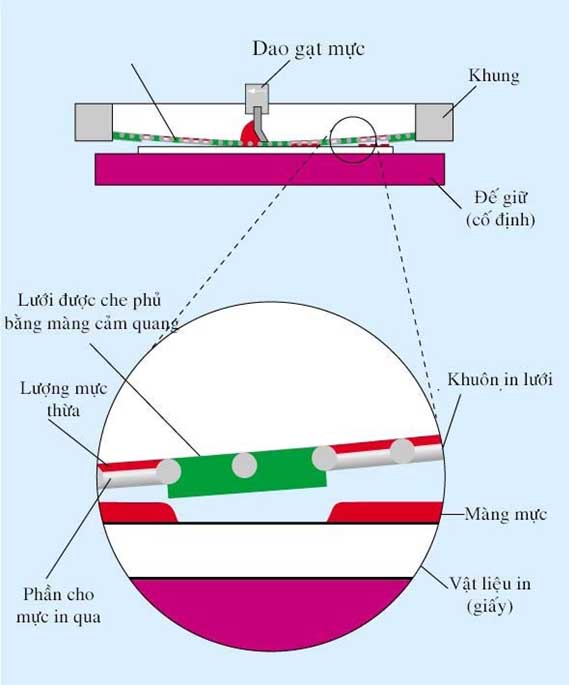

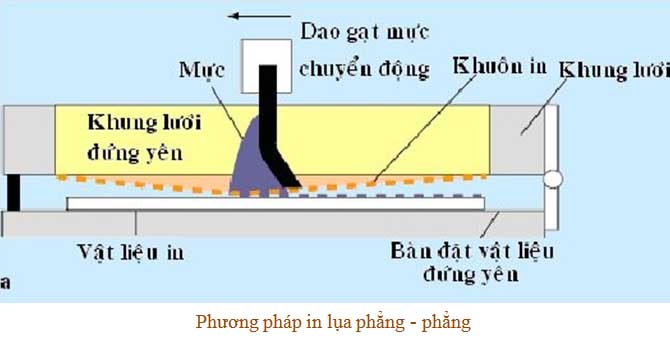

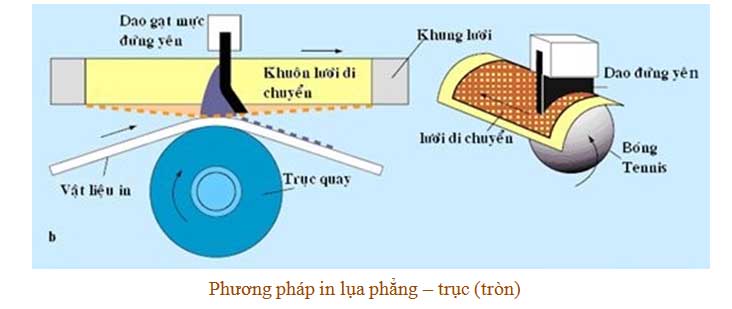

It is a method of printing through. The printing mold is made of a wooden frame. Printed components and non-printed components will be created on the mesh surface. Unprinted components will be sealed, printed components will not be covered.

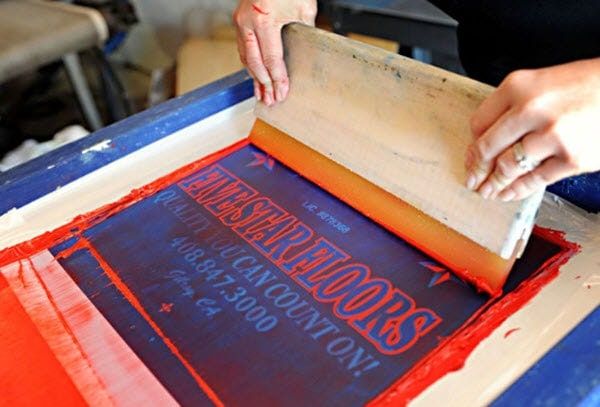

When printing, people will pour ink into the mesh frame and use a squeegee to scrape off the ink. The unprinted components are covered so the ink cannot pass through, and the printed components are not covered so the ink will pass through the mesh onto the printing material placed below.

Today, the types of nets used are of artificial origin such as plastic fibers or fibers

metal.

Typical products of screen (silk) printing: Fabric, t-shirts, toys, packaging, bags, cards, Visit Cards…

Advantages of silk screen printing

Like other printing techniques, screen printing also has its own advantages and disadvantages. So when learning about this technique, you need to grasp the outstanding advantages and disadvantages to make the best choice.

On the plus side, screen printing has lower printing costs compared to other techniques. Because this is a traditional printing technique, there is no need to invest in too much modern machinery.

With screen printing, customers can choose to print on many different materials such as: Fabric, paper, plastic, glass, ceramics, rubber, etc., all producing products with sharp image quality. Besides, customers can choose to print in many colors according to their wishes and needs.

In addition, the process of silk screen printing can also be done for small units printing in small quantities. Customers can choose to proactively perform quick printing when urgently needed. After printing, the product has a beautiful silhouette and is highly durable during use.

In lụa gia công có thể thực hiện được trên mọi chất liệu

Disadvantages of processed screen printing

Besides the outstanding advantages, screen printing also has certain disadvantages.

One of the main disadvantages is that it takes a long time because each color and print uses a separate mold.

Images are easily broken during the printing process or after printing if the ink is not of good quality.

When screen printing, the ink adheres quite tightly to the material, so it is very difficult to clean. At the same time, during the process, the ink can be smeared on the outside if not careful.

Screen printing film panels require vector files and design files. The image files will not be usable, so it takes quite a while to execute.

In addition, silk printing is very convenient for creating colorful shapes or charm colors. At the same time, it takes a lot of time and process to perform, so it is only suitable for small orders and small quantities.

Classification of common screen printing types

Besides traditional screen printing, this technique has now developed many different methods suitable for each specific type of material. Depending on the product’s requirements, choose the appropriate screen printing method. Some common types of screen printing include: Overlapping color screen printing, heat transfer screen printing, modern 3D screen printing.

Cách pha mực khi in lụa

Overlapping color screen printing

Overlapping color screen printing, also known as Tram printing. This is one of the difficult printing techniques, requiring sophistication and meticulousness during the implementation process.

Normally in printing we often use 4 main colors: Red, yellow, blue, black to create all other colors. Overlapping screen printing is also based on those principles to mix light and dark colors, creating images.

The most difficult point in the color overlay screen printing technique is to export the film and capture the entire remaining copy of the process, still the same as normal screen printing. That’s why the color overlapping screen printing technique requires workers to be highly skilled, sophisticated and meticulous.

Overlapping color screen printing has some outstanding advantages such as: Printed images have beautiful colors, more attractive than monochrome screen printing. Diverse printing colors, meeting all customer needs.

Besides, the silk-screen printing method overlaps the ink color more easily into the material, helping to save ink while still creating sharp, impressive images.

In lụa chồng màu tạo ra hình ảnh sắc nét, đẹp mắt

Overlapping color screen printing is done in 4 steps:

– Print one color layer.

– Blow dry temporarily.

– Continue printing the 2nd and 3rd layers depending on the product’s requirements.

– Dry at a temperature of 120-140 degrees Celsius.

Heat transfer screen printing

Thermal transfer screen printing is an indirect method of printing from the ink layer to the product surface through an intermediate paper layer thanks to the heating pressure of high temperature.

The principle of heat transfer screen printing is to use heat to press ink from the base paper, gradually absorbing it evenly into the surface of the product. This process takes place slowly to create the best quality product.

How to heat transfer screen screen printing:

Print glue on printing paper and products, under the influence of high temperature they will slowly release and mix with the ink and penetrate evenly across the surface. Use the printing screen 2 – 3 times, smoothing evenly and gently.

The printing process is done quickly. Each time from 10 – 12 seconds under pressure ranging from 4 – 6kg, temperature 160 – 1800 degrees Celsius.

Kỹ thuật in lụa chuyển nhiệt

Advantage:

– Printing film and heat transfer paper can be stored for reuse.

– Can print on many materials such as plastic, fabric,…

– Perfect product quality with sophisticated, beautiful lines. The printed details are sharp in every line.

– After printing, the product is durable and beautiful over time.

Disadvantages: Cost is much higher than other methods and more difficult to perform than regular screen printing.

3D screen printing technique

3D screen printing technique brings many special, beautiful and attractive effects with high quality, unique and beautiful products. 3D printed products are often sold at better prices and are very popular in the market.

Currently, 3D screen printing technology is a commonly used method for large, high-volume orders. Printed products, if they are images, will use the 4 or 6 color separation method. The process is printed in order: White, yellow, red, blue, black and secondary color.

3D screen printing technology produces images that are more vivid, brighter and more dimensional. All thanks to the colors of silk screen printing ink being more beautiful and having a unique surface effect compared to the ink colors of other fabrics. 3D silk screen printing products are guaranteed to satisfy all aesthetic needs, even for the most demanding people.

Digital 3D silk printing process:

Screen printing process

Step 1: Prepare the frame and mix glue: The frame can be made of wood or aluminum alloy that has been washed and dried. The frame can have many different shapes, but most are used as curing frames. Japan.

Step 2: Take copies

Step 3: Mixing ink: Printing ink needs to be carefully prepared, especially suitable for each material being printed.

Step 4: Test print and monitor the screen: You put ink on the trough to scan onto the mesh, paying attention to scanning both sides evenly, then dry it thoroughly, continue to stick the film on the outside of the mesh, take tape to tape the 4 corners, and take glass plate to press the film onto the mesh and expose it to sunlight for 3 minutes or use a drying machine, then you can check your product.

Step 5: Print output: Evaluate the quality of the test print and see that the product meets the necessary criteria, then you can start mass printing.

Step 6: Wash the frame: After drying, remove the film and wash the frame thoroughly to prepare for the next printing.

Nowadays, screen printing is often used less than before because the printing process is cumbersome and large quantity printing often requires very limited steps, they are replaced by digital printing, inkjet printing, laser printing… more.

Application of silk screen printing in life

Up to now, silk screen printing is still very popular in life. It appears in almost every industry, on every material with sharp, beautiful images.

One of the most popular applications is screen printing on t-shirts, screen printing on paper, screen printing on plastic, printing on packaging, even materials such as electronic circuits, metal, handbags, and leather shoes. , cold towel,…

Applying silk printing techniques on all materials produces quality images, clear and detailed lines and patterns, ensuring all aesthetic requirements. Especially when applying screen printing techniques on fabric, 3D silk printing will create the most vivid and realistic images.

Silk-screen printing of backpacks

3D silk printed backpacks and handbags are lifelike

Silk-screen printing of t-shirts

In addition, uniform silk printing is also very popular on sportswear and fun couple outfits. Especially with lifelike 3D printed silk dresses, girls will become more graceful and seductive than ever.

Print t-shirt uniforms

Silkscreen printing on paper

In addition to applying screen printing on fashion products, process screen printing is also an additional printing method for finished products after local UV coating, tags, name cards,…

Print on paper, card

Screen printing on plastic

Silkscreen printing on plastic

Printed on packaging

Silk printing on packaging

Print wedding invitations

With the outstanding advantage of clear print quality and little fading, manual screen printing is also used when printing wedding invitations or images on quality backpacks and handbags.

Silk printing on wedding invitations

The screen printing process that everyone should know

This process includes many different steps, each step is a necessary step so you cannot skip it. If you want to know what screen printing is, see the screen printing process below:

Prepare the frame and mix the glue

Frames can be made from plastic, wood, or metal, but are most commonly made from aluminum for durability. The frame needs to be washed and dried. There can be many different shapes, but the most commonly used types of frames are square and rectangular.

Used on many garment products

Take copies and mix ink

Take the drawing that needs to be printed, then you can use tiny silk frames with many small holes to print. Screen printing mesh needs to be done meticulously to avoid unnecessary mistakes. Depending on the printing material, you will choose the appropriate ink. This step is very important to avoid damage to bags and backpacks.

Test print, watch

Put ink on the trough to scan onto the screen printing screen, scan both sides evenly and then dry thoroughly. Then continue to paste the film on the outside of the printed mesh, carefully pasting the 4 corners. Dry for 3-5 minutes in the sun or drying machine to check the quality.

Review and print

Once the test print is successful and the print is beautiful, you can proceed with mass printing. After printing, remember to remove the printing screen and wash the frame thoroughly for next use.

Silk printing technology is increasingly modern with machinery

Currently, silk printing has gradually been replaced by many printing methods such as digital, film, laser… However, some special bags still use this printing method. To have a good quality silk screen printing, you need extremely good staff skills. So if you are interested in high quality silk printed bags and backpacks, you can go to an attractive company below.

Tiếng Việt

Tiếng Việt 한국어

한국어 中文 (中国)

中文 (中国)