OFFSET PRINTING METHOD

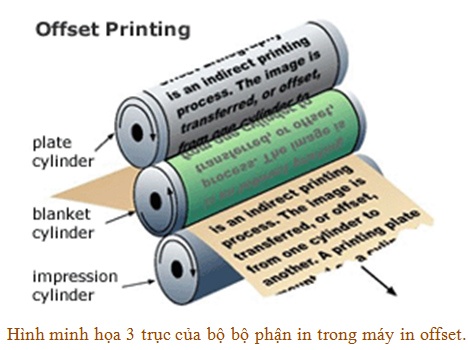

Offset is a flat, indirect printing method (the print receives ink transferred to the rubber sheet and then from the rubber to the paper).

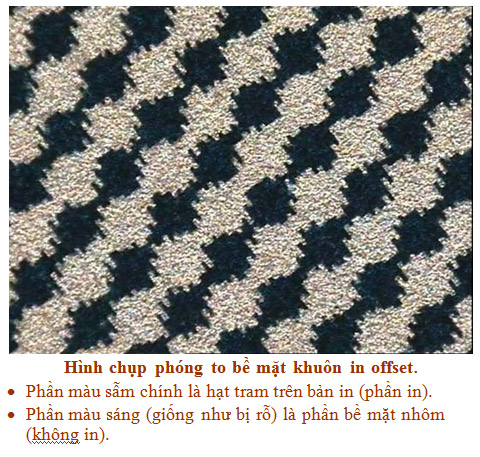

Offset printing is a printing method based on the principle of flat printing, which means that on the mold, images, writing and unprinted areas all have the same height (when looking at the surface of the printed plate, it is… flat as a sheet). paper). So how can it be printed? The secret is that here, people apply the repulsion between oil and water. The printing mold is made from a thin aluminum sheet (about 0.25mm). On the printing mold, the white part (not printed) has an aluminum surface, while the printing element (image, text) is made of a special plastic. called Diazo resin. Class

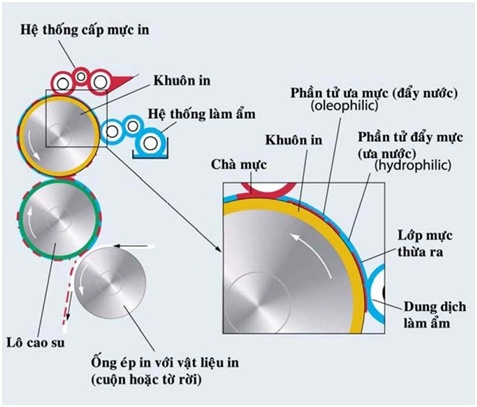

This plastic has the property of absorbing oil and repelling water, and offset printing ink is an oil-based ink. During the printing process, the surface of the printing mold is first rubbed with a thin layer of water. This layer of water will wet the non-printed area (which is the aluminum layer). Then the printing mold is inked. Because the ink is oil-based, it cannot stick to the white part of the printing mold (which is exposed to water), but only sticks to the printing element, which is an oil-loving diazo resin. That’s why even though the printing mold is flat, when rubbing ink, the ink does not rub all over the surface of the print, but only transfers to the printed element to form images and writing on the surface of the print. And then, when pressed and printed on the surface of the printing material, the image to be printed will be produced.

Why is it called offset (offset = transmitted): When printing, the print is not pressed directly onto paper or printing material like other printing methods, but will be pressed onto the surface of a rubber sheet, then this rubber sheet freshly pressed onto the paper surface. This is to create the most optimal ink transfer (transfer from hard surface –> soft –> hard).

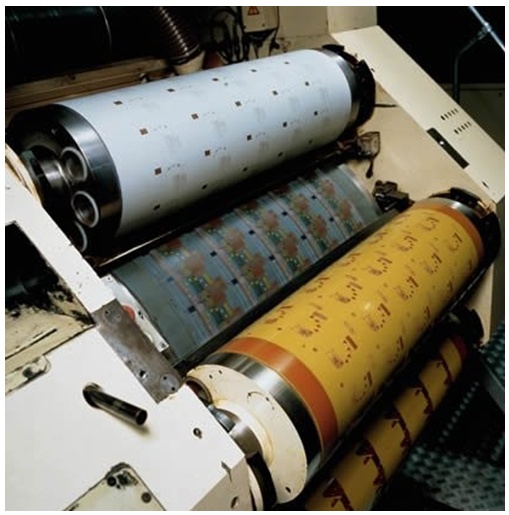

The top axis is the printing axis, the print will be mounted by rolling on this axis. The second shaft is a rubber bearing shaft, the surface is covered with a rubber sheet, and the bottom shaft is a printing press shaft.

The characteristic of this method is that the printed component and the non-printed component lie on the same plane. Based on the incompatibility between oil and water to create printed and non-printed components.

The non-printing component is hydrophilic, moistens the plate and therefore does not absorb ink.

The printing component repels water so it will attract ink.

Commonly used printing plates are aluminum or polyester.

Offset printers are often used to print on paper and metal plates.

Roll offset printers are mainly used to print newspapers and magazines. This type of machine usually has book cutting and folding parts.

inanquangcao.xyz

Tiếng Việt

Tiếng Việt 한국어

한국어 中文 (中国)

中文 (中国)